But determining the exact overhead costs is not easy, as the cost of electricity needed to dry, crush, and roast the nuts changes depending on the moisture content of the nuts upon arrival. Hence, the fish-selling businesses need to monitor the seasonal variations and adjust the cost pattern of the products. The use of predetermined overheads effectively incorporates the cost effects of seasonal variations in the product cost and price. However, the problem with absorption/traditional costing is that we have to ignore individual cash flow absorption bases and absorb all overheads using a single level of activity. Hence, this is a compromise on the accuracy of the overall allocation process. On the other hand, the ABC system is more complex and requires extensive administrative work.

Example of a Plantwide Overhead Rate

JKL’s profit plan for the new year includes $1,200,000 as the budgeted amount of manufacturing overhead. JKL allocates the manufacturing overhead based on the normal and expected number of production machine hours which are 20,000 for the new year. Therefore, the JKL’s predetermined manufacturing overhead rate for the new year will be $60 ($1,200,000/20,000) per production machine hour. Predetermined overhead is an estimated rate used by the business to absorb overheads in the product cost, and it’s calculated by dividing overheads by the budgeted level of activity. Both figures are estimated and need to be estimated at the start of the project/period. The overhead cost per unit from Figure 6.4 is combined with the direct material and direct labor costs as shown in Figure 6.3 to compute the total cost per unit as shown in Figure 6.5.

Calculation of Predetermined Overhead and Total Cost under Traditional Allocation

- At the beginning of year 2021, the company estimated that its total manufacturing overhead cost would be $268,000 and the total direct labor cost would be 40,000 hours.

- The first step is to estimate the amount of the activity base that will be required to support operations in the upcoming period.

- However, small organizations with small budgets cannot afford to have multiple predetermined overhead allocation mechanisms since it requires experts to determine the same.

- This chapter will explain the transition to ABC and provide a foundation in its mechanics.

- On the other hand, if the business wants to use actual overheads, it has to wait for the end of the month and get invoices in hand.

For instance, in a labor-intensive environment, labor hours were used to absorb overheads. On the other hand, the machine hours were used to absorb overheads in a machine incentive environment. For example, a single predetermined overhead rate is called a(n) overhead rate the recipe for shea butter has easily identifiable quantities of shea nuts and other ingredients. Based on the manufacturing process, it is also easy to determine the direct labor cost.

- The elimination of difference between applied overhead and actual overhead is known as “disposition of over or under-applied overhead”.

- In a company, the management wants to calculate the predetermined overhead to set aside some amount for the allocation of a cost unit.

- For these reasons, most companies use predetermined overhead rates rather than actual overhead rates in their cost accounting systems.

- Using the planned annual amounts for the upcoming year reduces the fluctuations that would occur if monthly rates were used.

- You will learn in Determine and Disposed of Underapplied or Overapplied Overhead how to adjust for the difference between the allocated amount and the actual amount.

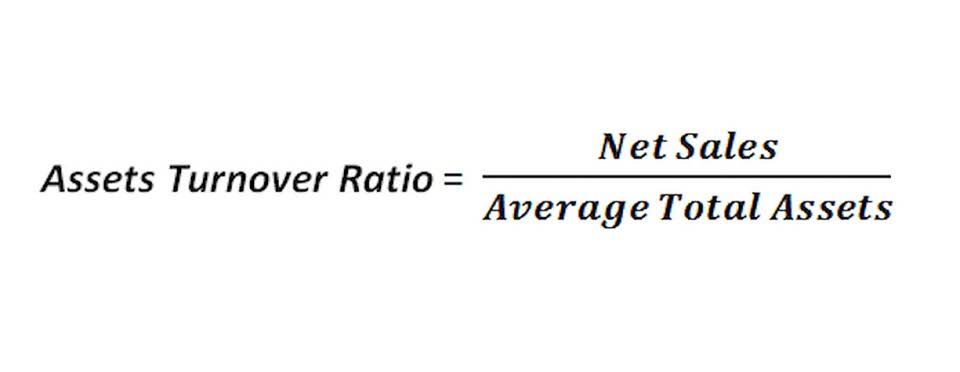

- Once a company determines the overhead rate, it determines the overhead rate per unit and adds the overhead per unit cost to the direct material and direct labor costs for the product to find the total cost.

Determining Estimated Overhead Cost

It is an integral part of the process of cost accounting, which helps companies determine the cost of their products and services accurately. Overhead costs are then allocated to production according to the use of that activity, such as the number of machine setups needed. In contrast, the traditional allocation method commonly uses cost drivers, such as direct labor or machine hours, as the single activity.

Basis

This complexity is driven by different factors, including but not limited to common activity for multi-products and a greater number of supportive activities for the production. However, if there is a difference in the total overheads absorbed in the cost card, the difference is accounted for in the financial statement. Complex overhead absorption is when multiple absorptions are required to allocate the cost of the support function.

- A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs.

- Businesses normally face fluctuation in product demand due to seasonal variations.

- Multiply the overhead rate by the actual amount of the allocation base used for each product to allocate the overhead costs to each product.

- In contrast, the traditional allocation method commonly uses cost drivers, such as direct labor or machine hours, as the single activity.

- So, for every hour of direct labor used to produce widgets and gizmos, XYZ Inc. will allocate $50 of manufacturing overhead costs.

- The comparison of applied and actual overhead gives us the amount of over or under-applied overhead during the period which is eliminated through recording appropriate journal entries at the end of the period.

- As a result, management would likely view labor hours as the activity base when applying overhead costs.

- It’s a completely estimated amount that changes with the change in the level of activity.

- You can envision the potential problems in creating an overhead allocation rate within these circumstances.

- For instance, in a labor-intensive environment, labor hours were used to absorb overheads.

- A large organization uses multiple predetermined overhead recovery rates to allocate its expenses to the cost centers.

- Albert Shoes Company calculates its predetermined overhead rate on the basis of annual direct labor hours.

For example, we can use labor hours worked, and for https://www.bookstime.com/ calculating overhead for the store department, we can use the quantity of material to be used. The differences between the actual overhead and the estimated predetermined overhead are set and adjusted at every year-end. It’s a completely estimated amount that changes with the change in the level of activity. Companies need to make certain the sales price is higher than the prime costs and the overhead costs. In some industries, the company has no control over the costs it must pay, like tire disposal fees.

Leave a Reply